| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : HHS

Model Number : HHS-900

Certification : CE/ISO

Place of Origin : CHINA

MOQ : 1 SET

Price : USD:36000-90000/SET

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 50 SETS/MONTH

Delivery Time : 30 working days

Packaging Details : wood package /20-40GP/HC

Type : Tire Cutting Machine

Power(w) : 90kw~200kw

After-sales service provided : Video Service

Voltage : 380V/220v,Customer Request

Name : Tire Cutting Machine

Capacity : over 500kg/h,200-4000kg/h,1500 kg/h

Year : 2021

Product name : Scrap Tire Recycling Equipment,Rubber Tire Shredder Machine Waste Tyre Recycling Plant,Steel Wire Separation Waste Truck Tyres Recycling Machinery

Function : Tire Powder Recycling Machine

Raw material : waste tire sealing sheet,rubber scraps,truck tire,car tire

End product : rubber granules and powders,rubber granules/rubber powder,tire steel,tire fiber

Usage : Used Tire Recyling,Waste Tyre Dispose

Single Hook Debeader

This Single Hoop Wire Drawing Machine is used to seperate the steel wire in the Tire,after this process,the tire can be put into the tire shredder to get 50*50mm rubber blocks.

Technical Parameter

| Model | LSL-1200 |

| Working Capacity | 20-40pcs/hours |

| Max. Tyre Dia. Can be used | 1200mm |

| Motor Power | 7.5KW |

| Working Pressure | 13Ton |

| Oil cylinder telescopic length | 1200mm |

| Size | 4100x1300x1750mm |

Pictures

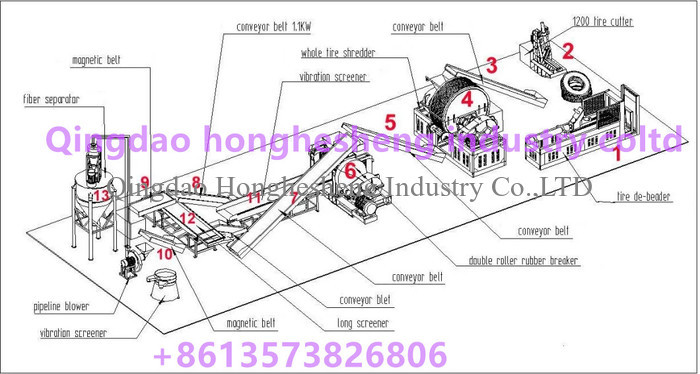

Full Automatic Production Line Description

If you need the other machines,contact me now.

| Tire debeader

| The first step in tire recycling procession Heavy duty body Hooks and cross pulling die made of 45# steel, tempered and quenched Equipped with protection frame avoiding the dangers during working Two series: hydraulic one and mechanic one Easy to operate and change spare parts (hooks and cross pulling die) |

| Tire cutter

| Cutting tires into pieces before shredding Small tire pieces are easier to process in shredder Knives made of YG-20 steel, long using time Hydraulic control One clamping cylinder and one cutting cylinder Equipped with a roller platform to process big tires |

| Tire shredder

| The high-capacity shredder was specially developed for direct size reduction of tires into cleanly cut tire chips, size 50x50 mm. cutting shafts for the production of larger tire chips are available high torque at low speed cut even the strongest tires into pieces. All construction characteristics are designed for continuous operation in order to achieve highest throughput rates at lowest costs. Extremely precise tolerances between the cutting knives produce cleanly cut tire chips at low energy consumption. The cutting knives made of high quality alloy steel can be re-sharpened and reused which increases the service life and reduces the operating costs. The complete cutting chamber is lined with hard wear plates. Large doors allow for easy access into the cutting chamber. |

| Tire cracker

| The shear between the two rollers will make tire chips into powders as well loosen rubbers, steels and textiles Roller body made of cast steel Surface of roller made of alloy steel, welded when worn out One flat surface roller and one teethed roller, high throughput of powders Bottom made of cast iron Emergency stop when overload Distance between the two rollers can be adjusted. Hard gear gearbox Equipped with screening machine, magnetic separator and fiber separator, 99% purified rubbers will be got. Finals: 8-30 mesh |

| Magnetic separator

| Muti-stage belt style magnetic separator can reach more purified rubbers Separated steels will be in one place, easy to collect Permanent magnet, no more power consumption |

| Fiber separator

| After the grinder, the nylon wires will be grinded into fluff; According to centrifugal force, density difference, the fluff will be separated. The spin fans inside the cyclone barrel driven by the motor throw the compounds to the wall, at this time, light fluff will be upwards and fall down into the inside barrel; heavy rubbers will fall down directly, so textiles will be separated |

| Pulverizing unit

| The pulverizing unit is made of 3 sets pulverizers with a cyclone silo. The pulverizer consists of frame, main motor, non-pole reducer, feeding device, adjusting device and a pair of rotating disc and fixed disc. The fine powders will be achieved by the grinding and shearing of the two pin discs. The machine is cooled by water and air to ensure the quality of the powders. Non-pole reducer can adjust speed of the feeding device to meet the material demands. The cyclone silo will collect the rubber power without dust Finals: 30-80 mesh |

|

|

Single Hook Debeader Waste Truck Tire Steel Wire Pulling Out Machine Images |